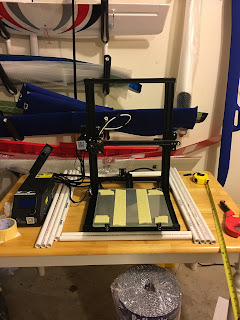

The Enclosure So here we are looking at the limitations of PLA for making RC Model aircraft. The main concern is the low temperature resistance. HIPS seems to be an interesting material with even more stiffness than PLA and much greater heat resistance. Unfortunately, like ABS, HIPS requires a very hot bed and an enclosure. The first thing I did was to make a frame big enough to hold the printer. I didn't include the control box in the enclosure because the control box needs to be kept as cool as possible. Once the frame was completed I covered the top, left, right and back sides with Reflectix an insulation material I got from Lowe's. I used 3M metallic tape (3M 3340) to secure the material to the PVC pipes. This tape is rated to withstand temperatures -40°F (-40°C) to 300°F (149°C) We left the bottom uncovered and only covered the front partially. The opening was covered using transparent plastic (Optix). We used the same tape to make a hinge one ...